P0970 is a diagnostic trouble code (DTC) that can appear on a Honda Accord’s onboard diagnostic system (OBD-II) when there is an issue with the transmission shift solenoid “C” control circuit.

The transmission shift solenoids are responsible for regulating the flow of transmission fluid to control gear shifting. When the OBD-II system detects an issue with the shift solenoid “C” control circuit, it will trigger the P0970 code and activate the check engine light.

Honda Accord P0970 Code Definition

P0970 is a diagnostic trouble code (DTC) that displays “Pressure Control Solenoid “C” Control Circuit Low.” It is possible for this code to be triggered for several reasons, and a mechanic needs to diagnose what caused it.

Errors are detected in one of the solenoid control circuits controlling pressure control solenoids. In P0970, OBD-II notes that a pressure control solenoid control circuit malfunction has occurred, specifically within the region of “C.”.

Pressure control solenoids are used in automatic transmissions to regulate the hydraulic pressure used to actuate gear changes and deactivate torque converters.

To select the correct hydraulic pressure, the powertrain control module (PCM) uses the engine load, engine speed, vehicle speed, and throttle position to control the pressure control solenoids.

PCMs, detect the P0970 trouble code when there is a discrepancy between the desired hydraulic pressure and the actual hydraulic pressure.

What Does the P0970 Honda Code Mean?

In order to control clutch pressure, the A/T clutch pressure control solenoid valve C is used. As the powertrain control module (PCM) controls the duty cycle, a spool in the A/T clutch pressure control solenoid valve C pushes the valve (the hydraulic pressure is proportional to the current).

To compensate for the difference between the actual current and the current commanded by the PCM, it measures the current flowing through the solenoid valve C of the A/T clutch pressure controller.

An open or short circuit in the PCM output circuit signals a malfunction, which is detected and recorded as a Diagnostic Trouble Code (DTC).

What Causes The P0970 Code?

The P0970 code may be caused by a number of factors, including:

- Possibly damaged electrical components, such as shorted wires or faulty connectors

- It is possible for the PCM or transmission control module to malfunction in very rare cases.

- Internal transmission fluid passages are blocked by hydraulics.

- A mechanical failure of an internal transmission.

- A pump that does not work at high pressure.

- Congestion or contamination of the transmission fluid.

- Fluid levels are too low in the transmission.

- Solenoids malfunctioning during pressure control.

What Are The Symptoms Of The P0970 Code?

A P0970 trouble code will likely cause the check engine light to illuminate the dashboard of the vehicle. It is also possible that the transmission warning light will illuminate, and the overdrive light will blink as well.

In addition to the transmission, there may be drivability problems, such as harsh shifting, transmission slippage, transmission overheating, and even transmission problems that prevent the transmission from shifting.

There is also a possibility that the transmission may slip into “limp-in” mode, and the torque converter clutch may not be able to engage or disengage. Fuel efficiency usually decreases with time for drivers.

How To Diagnose The Code?

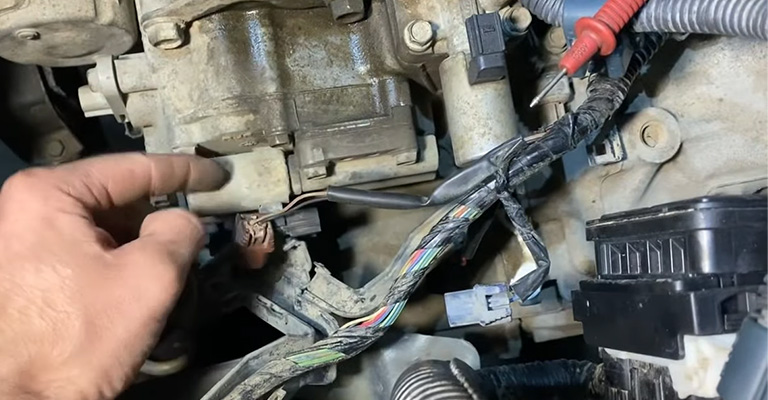

When determining the cause of the P0970 OBD II trouble code, we should first examine the simplest issues. You should check the level and condition of the transmission fluid as well as inspect the wiring harness along the transmission for signs of damaged wires and broken/corroded connections.

If nothing is found wrong, the transmission pressure control solenoid(s), valve body, transmission pump, and perhaps the ECU and TCM will have to be diagnosed in depth.

What Are Some P0970 Troubleshooting Steps?

It is recommended that you research any Technical Service Bulletins (TSBs) for the specific year, model, and transmission of the vehicle prior to starting troubleshooting.

In some cases, it can save you a lot of time in the long run by pointing you in the right direction.

Fluid & Wiring Inspections

Checking the fluid level and examining the fluid for contamination is the first step. It is recommended that you check the vehicle records before replacing the fluid to verify when the last time the filter and fluid were replaced.

A detailed visual inspection is needed to determine whether the wiring has obvious defects. You should inspect all connectors and connections for corrosion and damaged pins, as well as for security.

All wiring and connectors should be included in the transmission pressure control solenoids, the transmission pump, and the PCM.

Depending on its configuration, a transmission pump can be driven mechanically or electrically.

Advanced Steps

The advanced steps always depend on the vehicle for accurate performance and require the appropriate advanced equipment. An automotive digital multimeter and relevant technical references are needed for these procedures.

Before taking advanced steps, you should always obtain your vehicle’s specific troubleshooting data.

There is no standard voltage requirement for all vehicles; it varies from one to another. The transmission design and configuration may also influence the fluid pressure requirements.

Continuity Checks

For wiring and connections, 0 ohms of resistance should be read unless specified in the technical data.

When performing continuity checks, always disconnect the power from the circuit to avoid shorting the circuit and causing more damage.

A wiring defect that is open or shorted is a source of resistance or no continuity, which requires repair or replacement.

What Are Some Common Repairs For This Code?

- A fluid and filter change is required

- The defective Pressure Control Solenoid needs to be replaced

- Identify and repair or replace faulty transmission pumps

- Transmitter valve body repairs or replacements

- To keep passages clean, flush the transmission

- Corrosion removal from connectors

- Repair or replace faulty wiring

- Flash or replace defective PCM

How Does A Mechanic Diagnose The P0970 Code?

To diagnose a P0970 code, one needs to use a standard OBD-II trouble code scanner. Reputable mechanics will analyze freeze frame data from the scanner to determine if the code is present and if any additional trouble codes have been generated.

When multiple codes are found, the technician should address them in the order they appear. It will then be necessary to reset the trouble codes and restart the vehicle.

In this case, the mechanic will check to see if the code has returned. There is a possibility that it was detected in error, or your computer was experiencing intermittent problems if it hasn’t been caught.

If it persists even after the mechanic resets the code, then the mechanic should check the transmission fluid. Refilling or changing the fluid may be necessary if the fluid is low or dirty.

Fluid contamination may, however, cause the transmission to need to be repaired or replaced entirely.

The mechanic will then visually inspect the electrical components in the system, replacing any damaged or compromised circuits, connectors, and wires.

In the eventuality that the problem persists, a manual pressure gauge can be used to determine whether the hydraulic pressure is consistent with the manufacturer’s recommendations.

The pressure may be lower than it should be due to a defective pressure pump, solenoid, regulator, or blocked lines. Inspection, testing, and possible replacement are recommended for these components.

Ultimately, suppose the code P0970 has not been resolved after thoroughly inspecting the internal transmission and possibly the PCM or transmission control module. In that case, the technician will have to replace the transmission.

Following the replacement of a component, the mechanic must reset the trouble codes and restart the vehicle before moving on with the inspection. Whenever the problem has been fixed, the technician will know.

Common Mistakes When Diagnosing The P0970 Code

Diagnostic mistakes related to the P0970 code most commonly occur in failing to properly follow the OBD-II trouble code protocol.

To ensure thorough, accurate, and efficient inspections and repairs, it is essential to follow the protocol strictly.

The most common problem with high-pressure pumps is a damaged electrical component.

How Serious Is The P0970 Code?

Although the P0970 code is detected in the vehicle, it may still be drivable, but performance issues may occur with the transmission.

A severe transmission problem may render the car essentially immobile, as the car may have difficulty shifting or may not shift at all.

Damage can occur if the transmission issue is not addressed, even though the car is drivable. Consequently, P0970 should be addressed as soon as it is detected.

Final Words

Other drivability codes, such as torque converter clutch and shift solenoid codes, accompany this trouble code. Whenever possible, the codes should be dealt with in order they appear on the OBD-II trouble code scanner.