Research shows that there’s been a controversy about installing a VTEC (Variable Valve Timing and Lift Electronic Control) on a non-VTEC engine since both have different modifications. However, it helps to improve performance and fuel efficiency by altering the timing and lift of the valves.

So, is it possible to install a VTEC on a non-VTEC engine? It is possible to install, but it would require significant modifications and may not be practical or cost-effective.

Now, if you’re confused about how to install your non-VTEC engine with a VTEC, we will show you what VTEC and non-VTEC entail, their differences, and how to install a VTEC in a non-VTEC engine in this article.

What Is VTEC Engine?

VTEC (Variable Valve Timing and Lift Electronic Control) is a valvetrain system developed by Honda that allows your engine to have multiple camshaft profiles for different operating conditions.

The system uses hydraulic actuators to switch between the different cam profiles. This can provide improved performance and efficiency by optimizing the valve timing. Thus, it can lift for the specific engine speed and load conditions as well.

VTEC engines have been used in a variety of Honda and Acura vehicles, including sedans, coupes, and sport utility vehicles.

The system is often used to provide a balance between low-end torque and high-end power. It has become popular among enthusiasts and racers due to its ability to improve the performance of an engine.

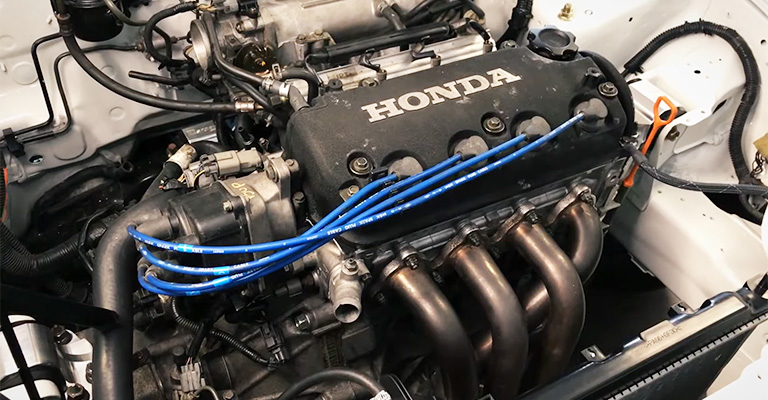

Non-VTEC Engine

A non-VTEC engine is a type of internal combustion engine that does not use Honda’s VTEC system. VTEC is a technology that allows an engine to optimize its performance by adjusting the timing and lift of the valves in the cylinder head.

Non-VTEC engines do not have this capability and instead rely on fixed valve timing and lift. These engines are typically found in older Honda vehicles or in lower-end models that do not require the added performance benefits of VTEC.

Can You Install VTEC On A Non-VTEC Engine?

Yes, you can install a VTEC on a non-VTEC engine, but it would need serious modifications on the non-VTEC engine bay to fit in appropriately.

Also, to install a VTEC system on a non-VTEC engine, you would need to make some changes to the engine. That includes installing new camshafts, rocker arms, and valve springs.

Furthermore, you would also need to add new sensors and a VTEC control unit to the engine. Likewise, the cost of these modifications can be significantly high, and it is not always easy to find the necessary parts.

In addition, it can be difficult to get the VTEC system to work properly on a non-VTEC engine, as the engine may not have been designed with VTEC in mind.

Altogether, it is generally not recommended to try to install a VTEC system on a non-VTEC engine. If you are looking to improve the performance of your engine, there may be other options that are more practical and cost-effective.

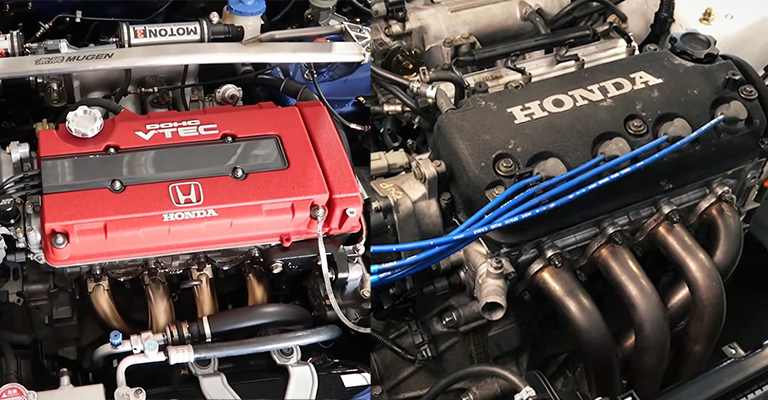

VTEC vs Non-VTEC Engines (The Differences)

There are several key differences between VTEC and non-VTEC engines. Below are some of those differences discussed to help you decide on which step to take.

| VTEC Engine | Non-VTEC Engine | |

| Performance | VTEC engines have increased power and torque and can switch between high and low lift cam profiles. This can increase the amount of air and fuel that can enter the engine. Thus, this can result in increased power and torque | They have limited power and performance. Hence, VTEC engines can deliver more power and torque at higher RPMs, while non-VTEC engines may struggle to keep up. |

| Fuel Economy | VTEC engines tend to be more fuel efficient than non-VTEC engines because they can operate in a more efficient mode at low and medium engine speeds, where most driving takes place | Non-VTEC engines may not be able to optimize their valve timing as effectively, leading to higher fuel consumption |

| Cost | VTEC engines tend to be more expensive to manufacture and maintain than non-VTEC engines, due to the complexity of the VTEC system | Non-VTEC engines are generally less expensive to manufacture and purchase than VTEC engines. This can make them a more cost-effective option for those who are looking to save money on their vehicle purchase or repair costs |

| Complexity and Simplicity | VTEC engines have a more complex design than non-VTEC engines, which can make them more difficult to maintain and repair | Non-VTEC engines are typically simpler in design than VTEC engines, which can make them easier to maintain and repair. This can be particularly beneficial for those who are looking for a reliable and low-maintenance engine for their vehicle |

| Ability to Adjust Valve Timing | VTEC engines can adjust or alter valve timing and lifts because it is not fixed and this improves performance | Non-VTEC engines cannot adjust valve timing, it is fixed, which can limit their performance potential |

| Reliability | VTEC engines are generally reliable, but the VTEC system itself can be prone to issues if it is not properly maintained | Non-VTEC engines, on the other hand, are generally simpler and this can make them less prone to breakdowns and failures |

Generally, VTEC engines offer improved performance and fuel efficiency, but at a higher cost and with a slightly higher risk of issues compared to non-VTEC engines.

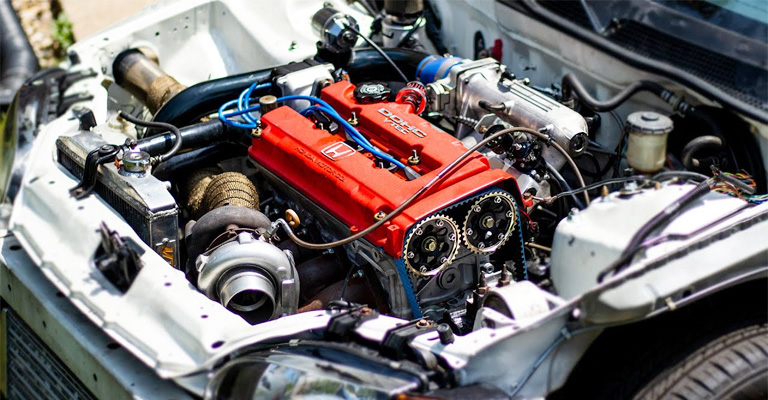

Installing VTEC Engine: Step-By-Step

Installing a VTEC engine in a non-VTEC vehicle can be a complex process that requires a high level of mechanical knowledge and expertise. It is important to note that VTEC engines are designed to work with specific vehicles and may not be compatible with every car or truck.

Additionally, the installation process can vary depending on the make and model of your vehicle. You can watch out this video to see the process https://youtu.be/OSfsOuWyqZ0

Here are the general steps for installing a VTEC engine in a non-VTEC vehicle:

Step 1: Assemble The Vital Tools And Equipment Needed

You will need a variety of tools to complete this process successfully. Some of these tools are

- Wrenches Set

- Sockets, screwdrivers

- Hydraulic jack

- A VTEC engine

Also, ensure to provide any special tools required for your specific vehicle and other additional parts or components that are necessary for the installation.

Step 2: Remove The Old Engine

Begin by lifting your vehicle using a hydraulic jack or a car lift. Then, remove the old engine by disconnecting all of the electrical connections, fuel lines, and coolant hoses, and then removing the mounting bolts that hold the engine in place.

Step 3: Install The VTEC Engine

Place the VTEC engine in the engine bay, and attach the necessary components, such as the oil pan, oil pump, and timing belt. Connect the electrical wiring and fuel lines, and refill the engine with oil and coolant.

Step 4: Test The VTEC Engine

Once the VTEC engine is installed, start your car to ensure that it is running properly. Test the engine by driving the vehicle around and observing its performance.

It is important to follow the manufacturer’s instructions and seek professional assistance if you are not confident in completing the installation. Working on a vehicle can be dangerous, and it is important to follow proper safety procedures to avoid injury.

Benefits of VTEC Engines

Here are some potential benefits of installing a VTEC engine.

- Improved Fuel Efficiency: VTEC engines can switch between two different cam profiles, allowing them to operate more efficiently at different forms of engine speeds. This can result in better fuel economy.

- Increased Power: VTEC engines can switch to a higher-performance cam profile at higher engine speeds. This can result in increased horsepower and torque.

- Reduced Emissions: VTEC engines can switch to a more efficient cam profile at lower engine speeds, which can help reduce emissions.

- Enhanced Engine Control: VTEC engines can adjust valve timing and lift based on engine load and speed. Thus, it can improve the overall performance level of the engine.

Conclusion

Installing a VTEC system on an engine that was not designed to support it would require significant modifications to the engine. That includes the addition of the necessary hardware and control systems. This would likely be complex and costly and is not something that can be done easily or inexpensively.

Altogether, the benefits and drawbacks of VTEC engines will depend on your specific needs and preferences. If you prioritize performance and are willing to accept potentially higher costs and reduced fuel efficiency, a VTEC engine may be a good choice for you.