Whether it’s speed racing or regular driving, a limited-slip differential improves the experience. The helical gears allow a larger contact ratio with other gears reducing the risk of wear.

But how does Helical limited-slip differential work? It works by sensing the torque needed by the wheels. Then, it supplies more torque to the wheel with more traction and limits it to the one with less. This differential also allows the wheels to rotate at different speeds, which is crucial when negotiating a corner.

In the article, you will learn how the helical limited-slip differential works and its advantages.

What Are Helical Limited-slip Differentials?

A limited-slip differential, also called Posi traction, was first developed in 1935. It garnered popularity decades later during the muscle car era in the 1960s. Like other differentials, the limited slip-differential works by transmitting power to the wheels at a different speed.

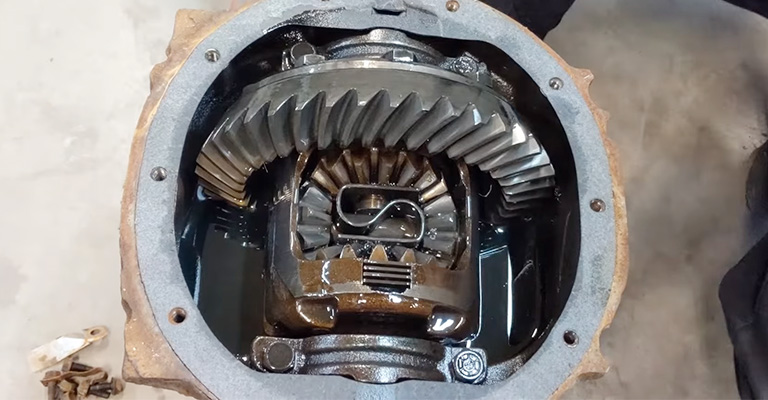

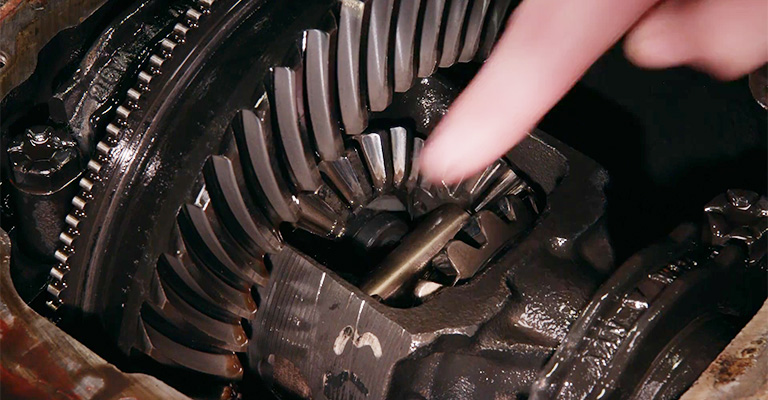

The limited-slip differentials use helical-shaped gears, known to wear slowly and carry a large load. These helical teeth align to the axis of the gear, and the first contact takes place on one end extending to other parts.

Besides transmitting the energy from the engine to the wheels, the differential allows vehicles to turn better. When negotiating a corner, the outer wheel goes further and faster and requires more torque than the inner one. Without the difference, the wheels have a hard time turning.

Although vehicles powered by rear wheels can drive without rear wheels, it’s highly disregarded. The wheels rotate at the same speed even in different tractions, which can damage the tires. Also, the force between the two wheels can affect the integrity of the axle.

How Do Helical Limited-slip Differentials Work?

The helical limited-slip differential supplies more torque to the wheel with better traction. This is necessary where one wheel has little to no contact with the surface. The wheel with better contact and traction gets more torque allowing the vehicle to move.

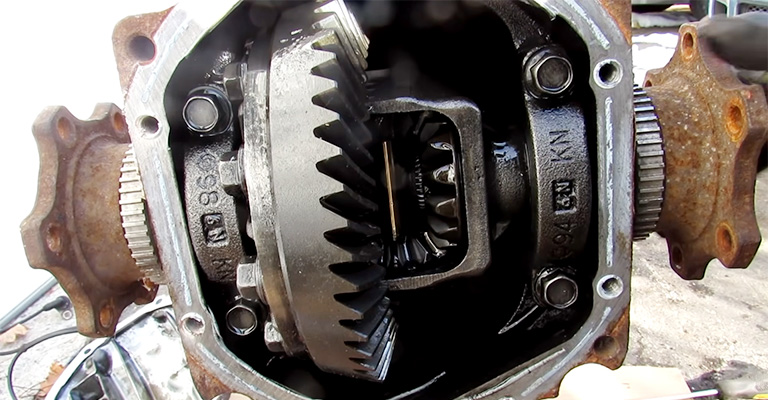

Like other differentials, the pinion gear rotates the ring gear. The differential housing, with pairs of spur gears and warm wheels, attaches to the ring gear. Thus the spur gears are meshed together and connect to the warm wheel on their helical gears.

Accordingly, the differential housing rotates along the ring gear when the vehicle has enough traction on both wheels. The three pairs of spur gears rotate at the same speed when the wheels are moving forward.

However, when one wheel loses traction, the spur gear with less traction rotates in the opposite direction and is slower. Then the spur gear with more traction rotates in the same direction as the ring gear on their respective warm wheel.

Despite the spur gear rotating in the opposite direction, the wheel on that side still gets torque. But the lower torque allows the wheel not to spin too much and wear the tire. This mechanism is the same that allows the vehicle to turn better in a corner.

Overall, most vehicles equipped with helical limited-slip differentials use sensors for monitoring. Also, some are controlled by a computer, increasing and decreasing spin on the wheels when needed.

What Are the Advantages of Helical-Slip Differential?

The helical-slip differential doesn’t only transfer driving force to the vehicle’s axle but has more advantages. They include:

1. Minimized slippage

Like other differentials, the helical-slip differential reduces slippage on the tires. The differential allows the wheel with a better grip to push the vehicle when it’s stuck.

2. Improved safety

The better supply of torque on the road surface improves the vehicle’s general handling. Thus the drivers have better control when cornering or driving through a slippery surface.

3. Responsive

The helical slip responds faster and better compared to other types of differentials. This is because the spur gears are connected directly to the warm gears that turn the axle. The differential also adjusts quicker when there is power demand on either wheel.

4. Heavy load

The Helical teeth in the limited-slip differential let it support more weight. They are aligned along the axis of the gear, allowing better contact with other teeth.

5. Not Prone To wear

Compared to the traditional gear, the helical differential doesn’t wear fast. This is because there is much contact between gears, spreading the wear along the teeth.

6. Reduced Wear on Shaft Axle

Without the limited-slip differential, the vehicle’s axle shaft could experience much wear during turning. The wear is from the wheels attempting to turn at the same speed when they should not.

Disadvantages of the Helical Limited-Slip Differential

Like most vehicle parts, the helical limited-slip differential has a few disadvantages. They include:

1. Reduced Torque

As the name suggests, the limited slip differential cannot provide 100% torque. Without enough torque, the wheel with a better grip might not push the vehicle out of a slippery surface.

2. High Maintenance Cost

Compared to the traditional open differentials, the limited slip is more costly to maintain. The more moving parts expose the vehicle to a higher risk of malfunction and high maintenance costs.

3. More Likely to Fish-tail

In a situation where the surface is much more slippery, like an icy road, the differential might fail. Since one wheel has too much torque than the others, if this wheel loses traction, it might slip and fishtail.

4. Require the Same Size Wheel

In a situation where you have a flat tire and you use the spare wheel, the differential might deactivate. This is possible if the replacement wheel is larger or smaller than the usual tire. Hence, to avoid mechanical problems, the wheel must be of the same size.

Conclusion

In a market with four common types of differentials, it’s best to learn how each works for clarity. With this knowledge, you can choose the favorable type more comfortably, and the parts work as expected. In this case, the helical limited-slip differential has several advantages and disadvantages.

The helical gear surfaces on the limited slip allow more contact and spread the wear. However, the power is sometimes too low to power a vehicle out on a slippery surface. Compared to other differentials, the limited slip is highly regarded and used in various high-end vehicles.