When assembling the engine block, it is essential to torque each bolt to the correct torque spec. Tightening the bolts too tight or loosely leads to oil and fuel leaks and excess vibrations as the engine runs.

So what is the torque spec for the valve cover? It ranges between 50 and 100 lbs depending on the material, engine model, and bolt placement point. Use the manufacturer’s manual to check for the exact torque spec for your valve cover. Also, use a torque wrench to apply a specific torque to avoid too much or low torque.

Read the article for more information on the torque spec for valve covers. This article shall also give ways of achieving the recommended torque without damaging the cover or the gasket.

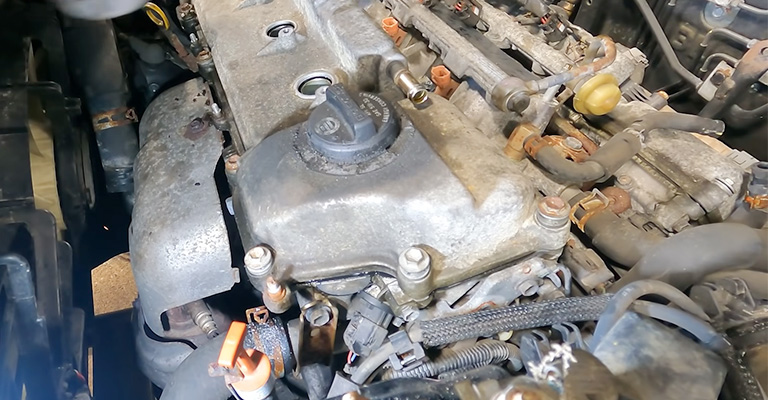

Torque Spec For Valve Cover – Everything You Need To Know

The valve cover is tightened according to the guidelines provided in the manufacturer’s manual. Every engine model has its unique torque spec dictated by factors such as the material of the cover and the cylinder head.

So the torque spec for valve covers ranges between 50 and 100 lbs. However, most of the bolts are torqued to 60 lbs with a half set of 40 lbs. Thus, heavy-duty engines with thick walls are tightened to between 60 and 100 lbs.

The primary purpose is to ensure the joint is tight to avoid leaks, and the joint should not be overtightened to damage the gasket or warp the cylinder head. Likewise, the silicone rubber gasket should guide your torque application.

Once you see the gasket being squeezed by the two mating parts, exert a little more torque to prevent fuel and oil leaks. To achieve the best torque spec for your valve cover, consult the manual’s guide for the exact torque spec for each bolt.

Do You Need A Torque Wrench To Tighten A Valve Cover?

The aim is to tighten the bolts to torque without damaging the bolt heads. Thus, the use of a torque wrench depends on the skill one has with the tightening of bolts.

Pros with the skills at hand can use a wrench or even a spanner to tighten the bolts. They have a way of feeling the extent of the tightness of the bolt. However, you may need to check the free-hand tightening with a torque wrench to confirm that all the bolts are tightened to torque.

Overall, the torque wrench is essential, especially when some bolts are to be tightened to a different torque spec.

What Is The Right Valve Cover Torque Sequence?

Applying torque to the valve cover bolts should not be done in any manner. The bolts are of different torque and need to be tightened in sequence. Why torque the bolts in sequence? This is to ensure you achieve proper joint integrity.

So, what is the proper torque sequence? There is no well-outlined sequence on how to tighten the bolts. However, experts’ advice on tightening the bolts from the center and moving outwards at the same time.

You should tighten the bolts in three steps.

- First, use your free hand to get the bolt into the hole and achieve a hand torque grip.

- After the threads are aligned, use the torque set at half or slightly above half the required torque and tighten the bolts in sequence.

- Set the torque wrench at the final range and tighten the bolts till the wrench clicks to affirm you have tightened to torque.

Factors To Consider While Applying Torque On The Valve Cover Bolts

Consider the following factors to uniformly and equally apply torque without damaging the bolts and the engine.

Torque Sequence

The torque sequence is the order in which you tighten the bolts. Start from the center and move outward on both ends. This allows the joinery parts to close up, leaving no gap in between.

Apply this sequence unless otherwise guided by the engine’s manual.

Gasket Selection

Different types of gaskets can be used while joining the valve cover and the cylinder head. If you use a rubber gasket, avoid tearing it with excess torque. Ensure proper alignment with the flange surface for the steel and metallic gaskets.

Bolt Lubrication

To avoid damaging the bolt threads, lubricate the bolt threads and then allow it to pick the first threads without applying force. You can lubricate the bolt hole if it’s an open-ended hole.

Bolt Selection

Some bolts are designed to withstand high torque, while others are soft and will snap on excess torque. Select bolts that will withstand the torque to be applied without failing. Consider the bolt material strength in comparison with the parts to be joined.

The Condition Of The Flange Sealing Surface

Most of the flange surfaces are smooth for the engine block. However, some are serrated, and one has to ensure the mating parts sit correctly on each other to leave no gap.

Confirm the alignment of the flange surfaces before tightening any bolt. Insert the bolts in their respective holes to confirm that they all pass through the two mating parts without forcing.

FAQs

Read the following frequently asked questions to assist in tightening your valve cover.

Q: Is It Necessary To Apply RTV On The Valve Gasket?

Yes. Applying the room temperature vulcanizing (RTV) silicone on the rubber gaskets is essential to offer a better sealant between the two mating parts.

The RTV has water-repellant features that help keep water from entering the engine block. It cures and dries at room temperature hence a more suitable sealant.

Q: How Can I Determine The Torque Spec For My Valve Cover?

At times, most bolts are not given the torque spec on the manual. However, you can use a torque calculator to determine the estimated torque spec for your valve cover.

You need to get the inner and outer diameter of the cover, the number of studs and their diameter, and the entry of the lubricant applied while torquing the valve cover.

Conclusion

Tightening the valve cover can be challenging if you don’t know the torque spec requirements. Apply between 50 and 100 lbs torque for the valve cover while checking not to damage the bolts and the engine block.

For accurate torque specs for the valve cover, check the manufacturer’s guide for the exact torque requirements. Use a torque wrench with a set spec to avoid applying less or excess torque.

While tightening, ensure the flange surfaces of the mating parts are correctly aligned to avoid the cylinder head warping or damaging the gasket.