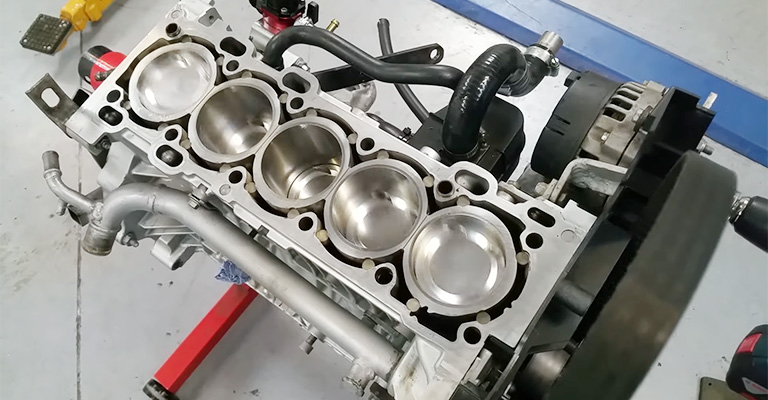

The engine firing order refers to the specific sequence in which the cylinders of an internal combustion engine ignite to generate power. This predetermined order is crucial for ensuring the engine runs smoothly, efficiently, and with minimal vibrations.

The firing order affects various aspects of an engine’s performance, such as power delivery, fuel consumption, and emissions. Each engine type has its own unique firing order, designed to optimize its performance and balance.

The purpose of this blog post is to provide a comprehensive guide for enthusiasts who want to better understand the firing order and its implications on engine performance.

Fundamentals of Firing Orders

A well-designed firing order can help minimize engine vibrations, optimize power delivery, and reduce mechanical stress on the engine components. Moreover, an effective firing order contributes to improved fuel efficiency and reduced emissions.

Factors affecting firing orders

Several factors influence the choice of a firing order for a given engine, including:

Engine configuration:

The layout of the engine’s cylinders (inline, V, or flat) affects the available options for firing orders.

Number of cylinders:

The total number of cylinders in an engine dictates the number of possible firing order combinations.

Crankshaft design:

The arrangement and orientation of crankshaft journals impact the firing order and the engine’s balance.

Engine balance:

Engineers aim to minimize vibrations and maximize smoothness by carefully selecting firing orders that contribute to an engine’s overall balance.

Power delivery:

The firing order should provide consistent and smooth power delivery throughout the engine’s RPM range.

Exhaust system design:

The firing order can influence the efficiency of the exhaust system and affect emissions.

Different Types of Firing Orders and Their Benefits

There are various firing order configurations, each with specific benefits depending on the engine type and application. Some common firing orders for different engine configurations are:

Inline-four engines:

1-3-4-2 and 1-2-4-3 are the most common firing orders for inline-four engines. These orders help achieve a balanced and smooth operation while minimizing vibrations.

V6 engines:

1-2-3-4-5-6, 1-4-2-5-3-6, and 1-6-5-4-3-2 are some common firing orders for V6 engines. These orders help ensure even power delivery and reduce vibrations.

V8 engines:

1-8-4-3-6-5-7-2 and 1-5-4-2-6-3-7-8 are typical firing orders for V8 engines. They contribute to smooth operation and even power distribution across all cylinders.

Each engine configuration has specific firing orders that provide the best balance, performance, and efficiency for that particular design. Engineers carefully select these orders to optimize the overall performance of the engine based on its specific use case and requirements.

Impact of the Firing Order on Performance

A. Engine balance and smoothness

The firing order plays a critical role in maintaining engine balance and smoothness. A well-balanced engine will exhibit reduced noise and vibration, contributing to a smoother and more comfortable driving experience.

B. Power delivery

A carefully designed firing order ensures consistent and smooth power delivery across the entire RPM range. The power generated from the combustion of each cylinder should be evenly distributed, preventing sudden fluctuations in torque that could negatively impact performance.

Smooth power delivery not only results in better acceleration and overall performance but also helps maintain the stability and control of the vehicle during driving.

C. Fuel efficiency

The firing order can also influence fuel efficiency by affecting the combustion process and the efficiency of the engine’s mechanical components.

An optimized firing order ensures complete combustion of the air-fuel mixture in the cylinders, reducing fuel waste and improving efficiency.

Additionally, a well-balanced engine with minimal vibrations and mechanical stress reduces energy losses, further contributing to better fuel economy.

D. Emissions and environmental considerations

The choice of firing order can have a direct impact on an engine’s emissions. A firing order that promotes complete combustion of the air-fuel mixture will produce fewer unburned hydrocarbons and other harmful emissions.

Moreover, an engine with a well-designed firing order tends to run more efficiently, consuming less fuel and producing fewer overall emissions.

By selecting an appropriate firing order, engineers can help minimize the environmental impact of internal combustion engines while still achieving the desired performance and efficiency goals.

Wrong Firing Order Symptoms

An incorrect firing order can lead to various problems, affecting the overall performance and functionality of an engine. Some common symptoms of an incorrect firing order include:

1. Rough engine idle

The engine may shake or vibrate excessively when idling, indicating uneven combustion forces.

2. Reduced power and acceleration

The engine may struggle to deliver consistent power, resulting in sluggish acceleration and poor overall performance.

3. Misfires

The engine may exhibit misfires, which occur when the combustion process fails in one or more cylinders.

4. Engine stalling

The engine may stall or shut off during operation, often accompanied by difficulty starting or maintaining a steady idle.

5. Poor fuel efficiency

An incorrect firing order can lead to incomplete combustion, resulting in increased fuel consumption and reduced fuel efficiency.

6. Increased emissions

Incorrect firing orders can contribute to increased emissions due to inefficient combustion and poor engine performance.

Causes of Firing Order Problems

Several factors can lead to firing order problems, including:

1. Incorrectly installed spark plug wires

If the spark plug wires are connected to the wrong cylinders or in the wrong order, the engine will fire in an incorrect sequence.

2. Worn or damaged ignition components

Damaged or worn spark plugs, ignition coils, or distributor components can disrupt the firing order, leading to poor engine performance.

3. Engine mechanical issues

Problems with the engine’s internal components, such as worn camshafts, valves, or timing belts, can affect the firing order and overall engine performance.

4. Incorrect modifications or repairs

If engine modifications or repairs are not performed correctly, they can lead to changes in the firing order or other issues affecting engine performance.

How to Diagnose and Fix Firing Order Issues

To diagnose and fix firing order issues, follow these steps

1. Check the engine’s service manual

Refer to the service manual for your specific engine to find the correct firing order and spark plug wire routing.

2. Inspect the spark plug wires

Check the spark plug wires to ensure they are connected to the correct cylinders and in the proper order, as specified in the service manual.

3. Examine ignition components

Inspect the spark plugs, ignition coils, and distributor components for signs of wear or damage. Replace any faulty components as needed.

4. Check the engine’s mechanical condition

Perform a compression test and inspect the camshaft, valves, and timing components for any issues that could affect the firing order. Address any mechanical problems as necessary.

5. Verify proper modifications and repairs: If you have recently modified or repaired your engine, ensure that all work was performed correctly and according to the manufacturer’s specifications.

6. Seek professional assistance

If you are unable to diagnose or fix the firing order issue yourself, consult a professional mechanic for assistance.

What is the Firing Order of 4 4-Stroke Engine?

The firing order of a 4-stroke engine depends on the specific configuration and the number of cylinders.

For a 4-cylinder, 4-stroke engine, the most common firing orders are 1-3-4-2 and 1-2-4-3. However, it’s important to note that the firing order can vary depending on the engine’s design and manufacturer.

To determine the correct firing order for a specific engine, consult the service manual or technical documentation provided by the manufacturer.

What is the Firing Order for 6 Cylinder Engine?

The v6 firing order can vary depending on the engine configuration and the manufacturer. However, some common firing orders for 6-cylinder engines are:

- 1-5-3-6-2-4 (for inline 6-cylinder engines)

- 1-2-3-4-5-6 (for V6 engines, particularly for some General Motors engines)

- 1-4-2-5-3-6 (for V6 engines, often found in Ford engines)

It’s essential to consult the specific engine’s service manual or technical documentation provided by the manufacturer to determine the correct firing order for a particular 6-cylinder engine.

What Does 1-8-4-3-6-5-7-2 Mean?

The sequence “1-8-4-3-6-5-7-2” represents a common firing order for 8-cylinder engines, particularly for V8 engines found in American vehicles such as Chevrolet and General Motors.

This firing order indicates the sequence in which the engine’s cylinders ignite to generate power.

In this case, the first cylinder to fire is cylinder 1, followed by cylinders 8, 4, 3, 6, 5, 7, and finally, cylinder 2.

The firing order is crucial for maintaining engine balance, reducing vibrations, and ensuring smooth power delivery throughout the engine’s RPM range.

What is the Firing Order for a 5 CYL?

The firing order for a 5-cylinder engine can vary depending on the engine configuration and the manufacturer.

However, a common firing order for inline 5-cylinder engines is 1-2-4-5-3.

It is essential to consult the specific engine’s service manual or technical documentation provided by the manufacturer to determine the correct firing order for a particular 5-cylinder engine.

Summarized table for the common engine series and their firing orders:

| Engine Series | Example Models | Firing Order |

|---|---|---|

| D-Series | D15, D16, D17 (D17A1, D17A2…) | 1-3-4-2 |

| B-Series | B16, B18 (B18A1, B18C1…), B20 | 1-3-4-2 |

| J-Series | J30, J32, J35, J37 (J35A1…) | 1-4-2-5-3-6 |

| K-Series | K20, K24 (K20A1, K24A2…) | 1-3-4-2 |

Remember that this table provides general firing orders for each engine series. To determine the correct firing order for a specific engine model, consult the service manual or technical documentation provided by the manufacturer.