The Honda L series engine is a family of inline-four-cylinder engines produced by the Honda Motor Company. Since its introduction, this powerful inline-four-cylinder engine has been used in various Honda models.

The L series engines are known for their reliability, fuel efficiency, and high-power output. In this article, we will take a closer look at the features and specifications of the Honda L series engine.

Introduction To The Honda L-Series Engine

Honda introduced the L-series engine in 2001 with the Honda Fit, a compact 4-cylinder engine. A range of 1.2-, 1.3-, and 1.5-liter displacements are available, referred to as L12A, L13A, and L15A, respectively.

Honda Civic and Fit Aria/City sedans (also known as Fit Saloons) have these engines in their five-door Honda Brio Fit/Jazz hatchbacks and four-door Honda Civic sedans. A Japanese-only version is also available in the Airwave wagon and Mobilio MPV.

This engine series has two different valvetrains. L12A, L13A, and L15A are equipped with (Japanese: i-DSI, or intelligent dual & sequential ignition).

For a complete gasoline burning, i-DSI uses two spark plugs per cylinder that fire at different intervals. Because of the better gasoline utilization, the engine has more power while consuming less fuel. There is also a reduction in emissions.

With two to five valves per cylinder, i-DSI engines reach maximum torque at mid-range rpm without needing to rev the engine at high RPMs, providing better performance without needing to elevate the engine.

A high compression, long stroke, lightweight, compact engine is another characteristic of the i-DSI that makes it a reputation for not using turbochargers in the performance category.

L15As with VTEC valve trains are also available. With 4 valves per cylinder, this engine focuses more on performance than efficiency. It reaches peak torque at higher rpm with a slightly higher redline.

Despite this, the vehicle offers a good balance between performance and fuel efficiency. A 10.8:1 compression ratio is found in the i-DSI and 10.4:1 in the VTEC.

In the past, the L-series were only available with a 5-speed manual transmission and a continuously variable transmission (CVT).

For the first time, an L-series engine was paired with a traditional automatic transmission with a torque converter in Canada and the United States.

A 5-speed manual transmission is the only transmission available with the L12A i-DSI on the European domestic market Jazz.

Besides the 1.6L Ford Kent engine, the L15A7 (i-VTEC) became a class-legal engine option for the SCCA-sanctioned Formula F competition in 2010.

Overview Of The Honda L Series Engines

L series engines are new designs for the global small platform / small-max series designed by Honda to replace the D series.

A number of innovative ideas can be found in the new L-series. Based on Honda’s “conventional VTEC unit,” the L series engine was designed against the well-established D-series engine.

The L series has smaller and lighter dimensions than the D series. Moreover, it is designed to be as efficient, achieving similar or better fuel economies while generating lower emissions.

It’s also unique how the L series complements Honda’s entire small vehicle platform, the Global Small Platform.

Designed To Be Compact

It is designed to help facilitate the realization of these features through the L-series engine. GSP’s main characteristic is its so-called “space efficiency.”

This allows maximum cabin space to be extracted from the small design, and the short engine bay plays an important role in this. In this way, the L series engine is designed to fit into a short and small engine bay.

These engines are developed to be super compact, enabling Honda to design short and small engine compartments for its ‘global small platform’ or ‘small max’ series of subcompacts.

Accordingly, the L-series engine is approximately 118mm or over 4.5 inches ‘thinner’ and 69mm or over 2.7 inches shorter (including the gearbox) than the ‘conventional 1.5l VTEC’ D-series engine.

It’s essential to have a thinner engine profile since L-series engines are transversely mounted, so the thickness directly impacts the engine bay depth. In reality, the difference in maximum thickness does not accurately reflect Honda’s engineering accomplishments.

As you can see from the comparison of the actual engine profiles of the D-series and L-series on the right, the L-series is much narrower than the D-series. There is about a 10% weight difference between the series and the D-Series.

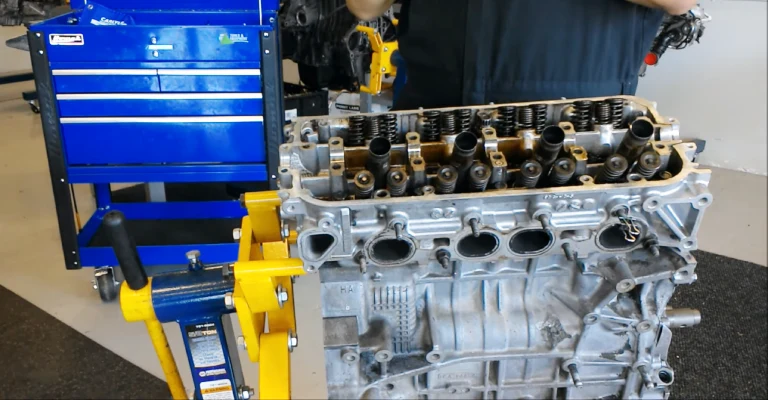

Compact SOHC Cylinder Head Design

An integral part of the thinner engine is the new, much more compact SOHC cylinder head design, which features a much smaller angle of 30 degrees between the intake and exhaust valves, instead of 46 degrees.

In addition, this allows the combustion chamber to be smaller and more compact, thus enhancing more rapid combustion of the air-fuel mixture.

An intake and exhaust rocker arm axle are combined in a novel manner to accomplish this. A line drawing of the D-series valve train is located on the right side of the photo.

You will notice that the intake and exhaust rocker arms each have their own axle, and their tips meet in the middle to rest on a single centrally-mounted camshaft. There are two trains of rocker arms in the L-series, which are moved inward toward each other.

Now, a single axle is shared by both trains of rocker’s arms, which are positioned directly above the single camshaft. It is now possible to make contact with the rocker and cam on opposite sides.

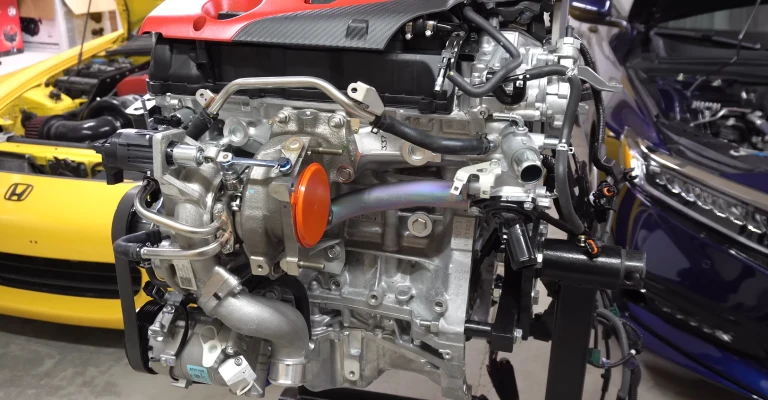

Highly Efficient Intake And Exhaust Systems

These new, highly efficient intake and exhaust systems are designed for the L-series cars. Its long-runner design provides high torque at low and mid RPMs.

The structure is lightweight and easy to install on the cylinder head because it is constructed of advanced, tough plastic. Usually, the intake manifold extends outwards from the cylinder head.

Due to the narrow cylinder head design of the L-series, the intake manifold is able to be placed closer to the engine. Long runner manifolds are huge, so they would take up a lot of space in any case. Therefore, the L-series intake manifold curves up and over and places the plenum above the engine.

In this way, the L-series is able to maintain its narrow profile by utilizing the vertical element of space. The little top also helps service or repair access into the engine bay and improves air circulation and cooling.

Superior Fuel Economy

With technologies that lower internal friction, the L-series achieves similar or even better fuel economy than the D-series. To extract more usable power from the combustion of air-fuel mixtures, internal conflict must be reduced.

List Of Technologies

The following is a partial list of technologies applied for this purpose.

The camshaft lobes are mounted on roller bearings that contact the rocker’s arm. Consequently, the friction between the camshaft and the rockers is reduced,

‘Pulverized molybdenum coating is used on piston skirts. First used on the 1995-2001 DC2 Integra Type-R, molybdenum-coated piston skirts first appeared on the famous B18C Spec R engine.

A high-pressure shot embeds the molybdenum into the piston skirts of the L-series after being ‘pulverized’ into powder form.

Adding molybdenum to the engine oil that already provides lubrication between the piston and the cylinder walls significantly reduces internal power loss through friction in this area, thereby reducing internal power loss. The company claims this is a world first.

There is an offset between the cylinder shaft (con-rod) and the crankshaft. The cylinder does not lie directly over the crankshaft, which means it cannot be directly overhead. To a small extent, its crankshaft is offset to one side.

As a result, the piston is not precisely vertical at TDC, but it is already slightly slanted.

In order to extract more power from the combustion process, the power stroke has a better ‘leverage’ on the crankshaft when the mixture burns. ‘Blade spring cam chain tensioners’ are used to tension the timing chain.

Innovations And Technologies To Enable Low Emissions

The L-Series employ several innovations and technologies to ensure low emissions and compliance with ULEV and EURO4 standards. Below is another non-comprehensive highlight:

Stainless steel exhaust pipes reduce weight and heat loss from exhaust gases by reducing weight and heat loss. Consequently, this heat conservation property results in a faster warm-up of the catalytic converter and cleaner exhaust emissions.

An oblique angle exists between the catalytic converter itself and the engine’s downpipe (see diagram). By doing this, the exhaust gas is also angled at an oblique angle as it enters the catalytic converter.

Increasing the area of contact between the exhaust gas and the catalyst within the cat enhances the cleaning efficiency, reducing emissions.

As a result of EGR, the L’Series emits fewer emissions. EGR operates based on the principle that power demand is deficient during light to medium operations. It’s more important that the engine runs steadily and that fuel economy and low emission levels are essential.

EGR reroutes some of the exhaust gases into the combustion chamber, mixed with new fuel and air, and then returns. Thus, the unburned energy that is usually released into the atmosphere can be recovered.

Final Words

So far, we have examined the L’Series engine as a whole. L’Series engines come in several variants, as is well known.

According to the technology implemented in the cylinder head, they can be broadly categorized into two categories.

I-DSI and VTEC are the two categories that belong to each of these technologies. Each has specific goals and achievements.

Other Honda Engine series –